What to Look for in a Sustainable Packaging Design

Sustainable packaging designs are all the rage, and for good reason. Not only are they promoting a more circular packaging economy but they’re also helping reduce the carbon footprint associated with the activity. With the world warming at an alarming rate, making impactful changes to packaging design and manufacturing is key to lessening its negative effects on the environment.

But with so much literature out there about sustainable packaging design, it can feel confusing to know where to start. Here, our Head of Design and Marketing, Matthew Kay, sets the record straight – and advises you on what you should be looking for.

What is a Sustainable Packaging Design?

Definitions vary about what a sustainable packaging design is. For us, it’s more than just the package itself. As a minimum, it’s:

- How and where the materials used to manufacture the package have been sourced from

- The entire manufacturing and production process

- All elements of the supply chains involved in creating and distributing the package

- Suitability for transport and logistics, including storage optimisation

- Ease of handling – a package might be the most sustainable out there, but if it’s not appealing or easy to use, there’s a huge barrier to adoption

- Considerations for what happens when the package reaches the end of its life (is it recycled, repurposed, reused?)

Sourcing Sustainable Packaging Materials

One of the more obvious factors that contributes to a sustainable packaging design is what it’s made from. As standard, a sustainable box uses materials that are fully recyclable or biodegradable and made from recycled or repurposed materials.

Take the corrugated cardboard we use to craft standard and bespoke packaging. It’s certified by the Forest Stewardship Council®, meaning the cardboard products we manufacture and supply are from responsibly managed forests. The board isn’t solely used for the outer box, though – we use it to make various elements of packages.

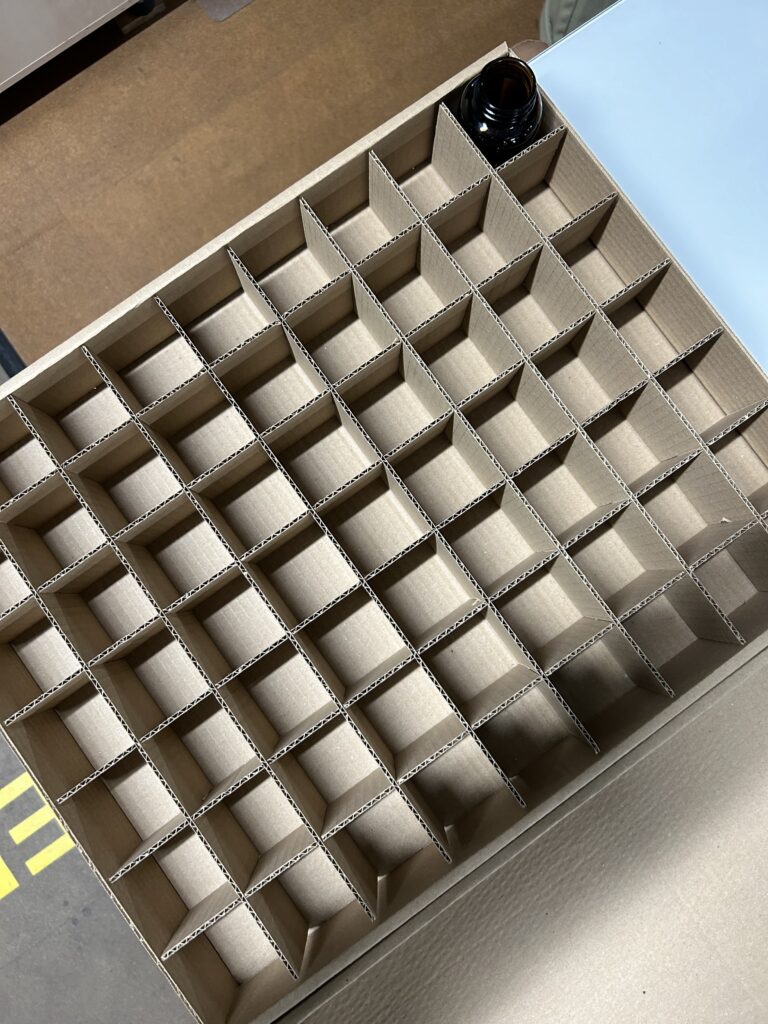

For instance, these inserts to keep an FMCG customer’s glass bottle goods secure:

Sustainable packaging inserts for a glass packaging manufacturer

Our specialist designers used CAD engineering to produce these bespoke fitments to reduce movement of the bottles. Subsequently, risk of breakage decreases, too. There are numerous board grades to choose from when manufacturing with corrugated cardboard. So, our designers made sure to select the one that offered the required strength to keep the bottles upright and protected during handling – without compromising the environment.

Sustainable Packaging Ancillaries

Likewise, the sustainable palletwrap we use to secure packages and pallets for transportation is fully recyclable. It’s made from at least 30% PCW recycled waste, too. This makes it exempt from the Plastic Packaging Tax, one of the newer pieces of packaging legislation hoping to draw businesses away from single-use plastics.

By minimising – or completely omitting – the need for single-use ancillaries that are unrecyclable and/or from virgin materials in your packaging design, you’re maximising the sustainability of the package.

Manufacturing Sustainable Packaging

Whilst these types of materials are paving the way to a more sustainable packaging sector, there’s no hiding from the fact that manufacturing is an energy-intensive industry. But what also hiding away (wrongly) are the huge improvements and innovations that have been made across the sector. And, which are empowering more sustainable packaging manufacturing day in, day out.

For instance, simple changes to the layout of machinery in a factory. At Greyhound Box, we’ve optimised where our machines are positioned across our 4,620m2 premises, so travel time between complimentary machines is as little as possible. Our team now works more efficiently, able to produce more boxes in the same amount of time as before.

Optimising the layout of machinery at the Greyhound Box factory

Once the flat boxes have been produced, our electric forklift trucks move them between our factory and warehouse. They’re then loaded onto pallets ready for distribution to the next stage of the supply chain. Again, the use of electric (rather than fossil fuel powered) trucks decreases the amount of nasty emissions we release into the atmosphere, contributing to a more environmentally responsible manufacturing process.

An electric forklift truck in use at Greyhound Box

Getting Started with Sustainable Packaging

There’s so much more that goes into a sustainable packaging design. The materials used, manufacturing processes, supply chain operations, and what happens to the box once it reaches end of life…

…these are just four key factors for those starting out their switch to more environmentally responsible packaging!

For advice and support on choosing the right sustainable packaging design for your product or goods, please get in touch with Matthew.