Technology & Innovation

Deploying Technology for Innovative Packaging

An Innovative Approach to Packaging

Here at Greyhound Box, we infuse our packaging expertise with advanced technology and machinery to deliver secure and impactful cardboard boxes to our clients. We utilise cutting-edge technology to create bespoke packaging creations that enhance our clients’ supply chains and establish a unique impression by intertwining design with functional features.

Premium Production

Our range of machinery allows us to manage various aspects of the packaging production process. The machinery that we utilise along with the high-quality cardboard that we source means we can produce superior quality cardboard boxes. Together, our machinery covers all of our production needs, producing boxes of all styles and sizes, from the smallest boxes for cosmetics to huge heavy-duty pallet boxes. In addition, we carry stocked board of various grades to immediately react to clients’ urgent requirements and/or produce smaller than standard quantities.

Printer- Slotter Machinery

In our factory, we use TCY Machinery’s equipment. We predominately use this printer-slotter machine for our medium-large-format cardboard box production and any printing that is required. The machine includes a highly accurate printing registration to deliver the client’s chosen design with incredible accuracy.

Wide-Ranging Conventional Slotters

For wide-ranging conventional slotters, we utilised machinery produced by both Mecanelec and SOLARCO. These allow us to produce short and middle-run projects in a rapid timeframe. They can accommodate scheduling the production of large & small-format boxes.

Die Cutter Machinery

The nick-free, multiple-out, die-cutting machine produced by Baysek is designed to conquer difficult jobs that traditional rotary and flatbed die cutters struggle to efficiently accomplish. Plain boards go in, and then a cutting form impresses onto the flat board to create the intended folds and designs, producing complex batches of cardboard boxes.

Glueing & Stitching

Our secondary machinery provides our team with a great range of options to quickly and efficiently join boxes together. Whether it’s gluing hundreds and thousands of transit boxes or stitching tough pallet box sets, we have a portfolio to accommodate all scenarios. Our Sodeme, MultiNova, and Emba machines support with the gluing and stitching of boxes, delivering outstanding productivity, flexibility, and material efficiency.

Waste Compactor + Recycling Management

It isn’t just the machinery related to box production that helps us to optimise our practices, optimal ways to carefully dispose of waste are just as vital. Our mini waste compactor has significantly reduced waste disposal time, from the equivalent of a single person cleaning and collecting waste for 8 hours a day to just 15 minutes a day.

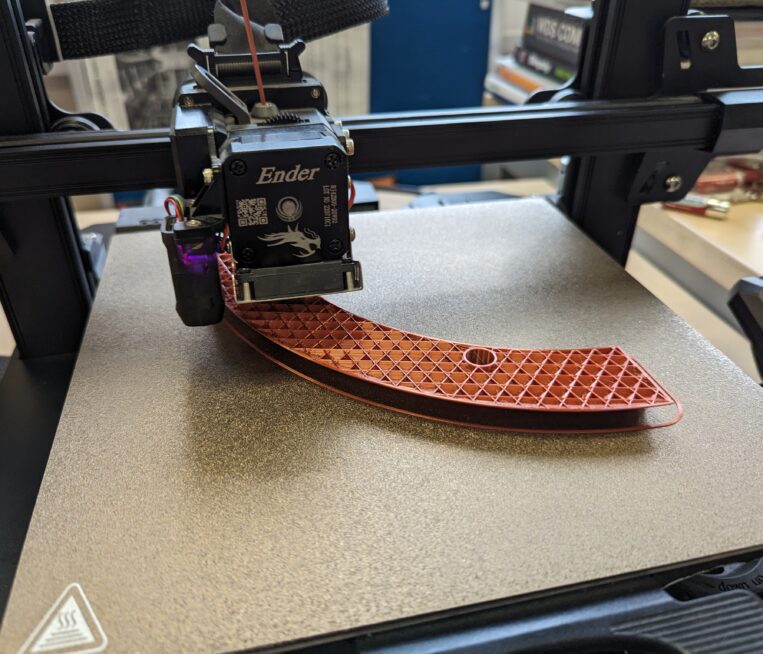

3D Printing

The introduction of the Creality Ender 3 S1 Pro 3D printer has revolutionised our approach to repairs, by enabling us to create precise spare and replacement parts to increase the longevity of our other machinery. Having the printer on-site allows us to produce these replacement parts in a rapid timeframe to avoid waiting for spares to be shipped and a machine being out of action for a longer period of time. 3D printing allows you to prototype and finetune designs as you go, allowing us to extract maximum performance. With the introduction of this 3D printer, we have been able to produce spare parts in a fraction of the time, and at a fraction of the cost. Furthermore, we’re not just limited to reproducing existing parts, we have the flexibility to curate completely bespoke parts that don’t even exist in the market. You could say the only limit is our imagination!

An Efficient Ecosystem

It is not only the machinery we apply, but how we utilise them, that allows us to create innovative packaging at scale. As a business, we have made conscious changes to the layout of the machinery in order to optimise efficiency and create a more seamless flow through our operations. Machines that are used to complete the same job type are positioned close to one another to reduce the time spent moving boxes between the different stages.

Applying CAD Design for Innovative Packaging

Our CAD machine plays a hugely important role in our commitment to delivering high-quality packaging solutions, not only this, it is a major component to building completely bespoke designs. The CAD machine empowers us to create concepts and prototypes before the build stage, allowing us to test boxes and share designs with clients prior to production. We rely on Impact by Arden Software, a heavyweight in CAD software tailored for the packaging industry which ensures we achieve precision in our bespoke designs, as well as the ability to pull from the industry-standard FEFCO Design Library. Impact supports multi-piece designs, specifically, keeping design components, manufacturing layouts, and 3D models linked nicely within the same project. This integration improves our workflow, allowing us to seamlessly transition from packaging conceptualisation to the final product.

Enhancing Sustainability Through Technology

Efficiency and sustainability are inextricably linked, whereby efficient processes naturally use less energy and result in less waste. We have clear ambitions relating to sustainability and have pledged to be net-zero by 2040. The technology we use plays a big part in making this a possibility. The efficiency gains through our innovative technology means less energy is consumed, less product results in waste, and water-based inks limit water pollution. To add to this, our breadth in machinery allows us to develop innovative packaging that is built with sustainability in mind.