Packaging Up 2024 at Greyhound Box

And just like that, we’re winding down and getting ready to put the lid on 2024. It’s been another positive and productive year at Greyhound Box, from enhancing our design capabilities with our new CAD area to continuing to collaborate with our lovely clients to find ways to increase the sustainability of their packaging.

We’ve wrapped up our best bits from 2025 below. We’d like to take this opportunity to wish you all a very merry Christmas holiday, however you choose to celebrate.

2024: The Figures

It’s fair to say our production team absolutely sleighed over the last 12 months:

- An estimated 4.5 million boxes left our Beza Road factory, weighing in at almost 1.4 million kilograms. That’s the equivalent of 43,750 Greyhounds (at 32kg each)!

- If you were to lay flat all the boxes we’ve manufactured, they’d cover an area 2.74 million meters squared – as far as it is from Greyhound Box in Leeds to Istanbul.

- The biggest box we produced came in at a healthy 1,185 x 985 x 1,030mm…

- …and the smallest at just 114 x 77 x 59mm.

Kudos, team!

The Greyhound Box team who’ve sleighed this year (but still made time to celebrate Halloween in October)

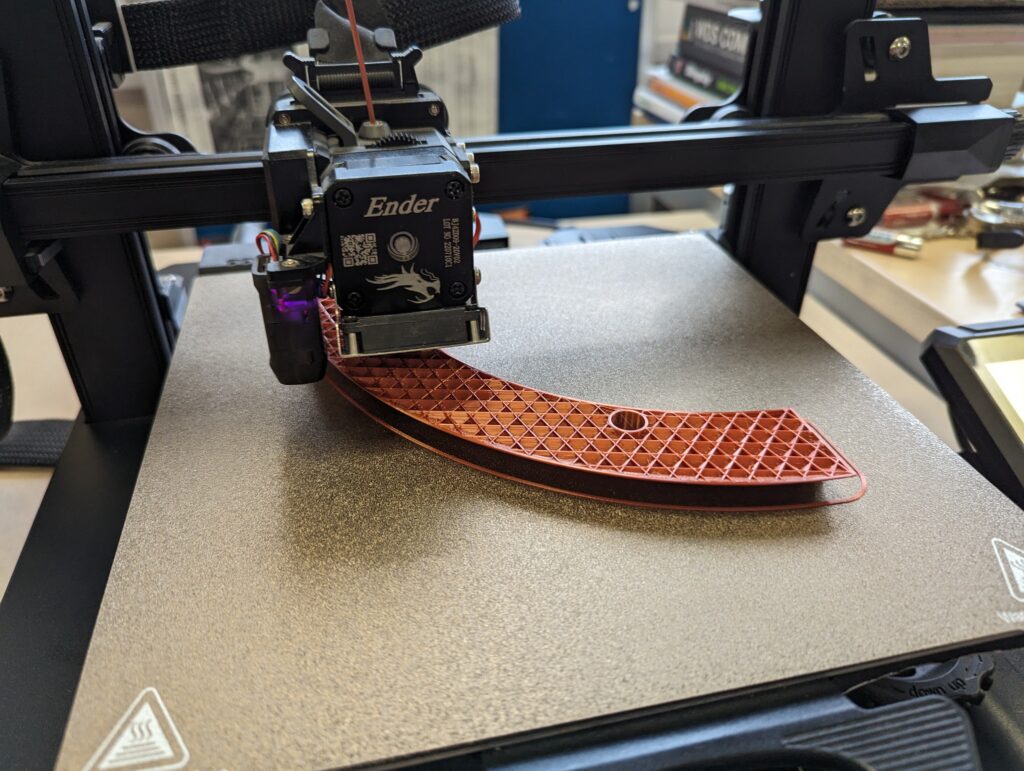

Enhancing Efficiencies with 3D-Printing

But they’re not all the stats we have for you. Six months ago, we introduced a 3D printer to the factory, which we’ve used to manufacture a host of parts for our packaging machines. Whenever an element has needed replacing or fixing, Cezary Biziewski, our Operations Manager, has risen to the challenge.

To date, the machine has run for around 720 hours, printing parts to keep our machines running efficiently – and importantly, reduce the risk of downtime. If the task is especially large or complex, the printer can spend an entire workday producing a single item! We’ve got through over 4,300m of PLA and PETG 3D printing filament this year, and we’re excited to see where Cezary can take our capabilities in 2025!

A shot of our 3D printer in action

Celebrating Our FSC Certification

One of the proudest moments for our whole team came at the start of the year. The Forest Stewardship Council® awarded us with their ‘Chain of Custody’ certification, which is recognised around the world. The accreditation gives assurance that the products we supply come from forests that have been managed responsibly, thanks to the FSC’s sustainable forest management models.

Magdalena Biziewska, our General Manager, led the project, and was delighted with the outcome.

Now that we’ve achieved the Chain of Custody Certification, we’re better positioned to continue raising awareness around both the sustainable forestry and social aspects of the supply chains our packaging operations rely on.

Magdalena Biziewska

With the FSC certification under our belt, we’re in a better position to encourage sustainability responsibilities along our entire value chain. That’s from where we source materials for our packaging solutions all the way through to our customers’ operations.

Our FSC certification achievement shows our continued commitment to the environment, reinforcing the strength of who we are at Greyhound Box.

Louise O’Brien, our Managing Director

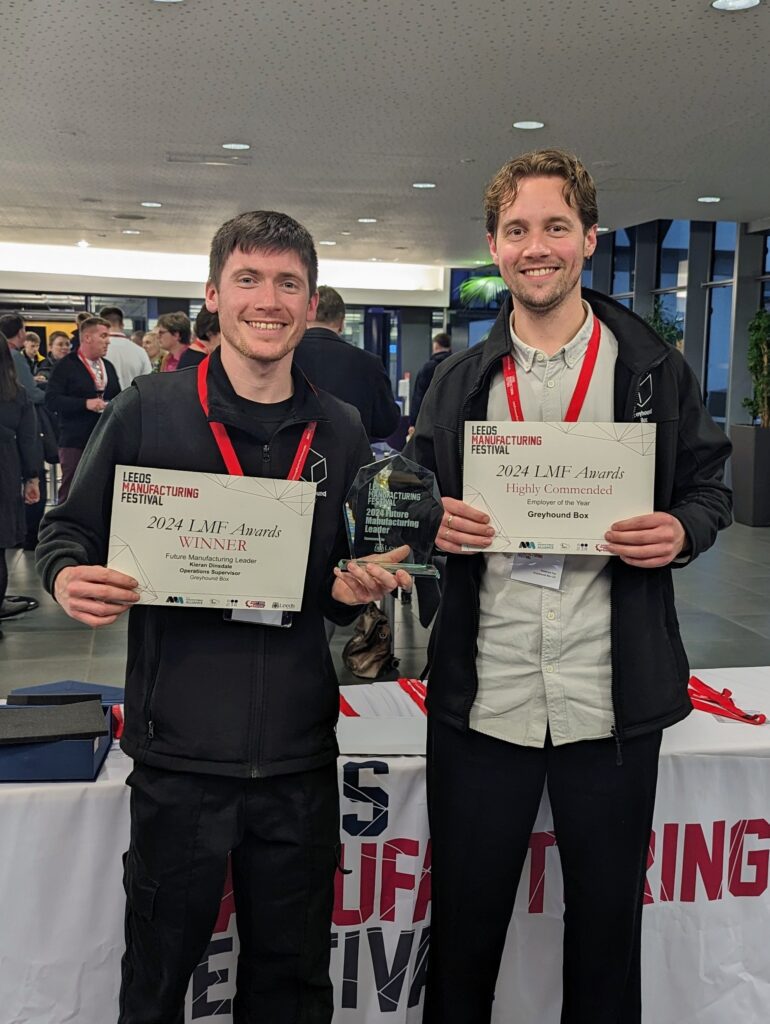

Double Congratulations at Leeds Manufacturing Festival Awards

Celebrations continued thick and fast throughout the year. In June, we attended the Leeds Manufacturing Festival Awards, which recognises the talent and contribution of younger people in West Yorkshire to our industry. Despite a record number of nominations being received for the awards, we were delighted to hear our very own Kieran Dinsdale announced as the winner of ‘Future Manufacturing Leader’. (Watch out, Louise!)

Yet the ‘congratulations’ didn’t stop there. Greyhound Box was also highly commended in the ‘Employer of the Year’ category, reflecting our continuous commitment to our people.

Kieran and Matthew at the Leeds Manufacturing Festival Awards 2024

Success for Our T-Level Placement Students

On such note, we were proud to see two T-level students successfully complete their placements with us. They spent time at Greyhound Box as part of their studies, with our whole team getting involved in teaching them about packaging manufacturing and design as possible. We wish you both the very best for your futures, and we’re looking forward seeing what our two new T-level students achieve in 2025.

Unwrapping our New CAD Area in Time for Christmas

It’s not only the next generation of manufacturers that had cause to celebrate at Greyhound Box in 2024. In November, we unveiled our new CAD area – much to the delight of our design experts!

To this…

…from this!

Our mezzanine is now home to a bright and welcoming CAD space for our people and clients alike. We’ve already spent many hours around the table testing and tweaking packaging concepts with customers to ensure only the most suitable solutions. Our clients are loving seeing us bring bespoke packaging ideas to life in real-time. Many have already benefitted from reduced order lead time!

Our desire to be able to demonstrate and adapt packaging concepts in front of our clients was the main draw for refurbishing the CAD area.

When we can collaborate with our clients from the comfort of the CAD area, we’re empowered to produce packages that meet the brief from the get-go and can then be manufactured at scale.

Matthew Kay, our Head of Design and Marketing

Matthew proudly standing in our new CAD space

Thank you to our Beza Road neighbours, Imageco, who designed and installed the forestry-inspired wallpaper which now surrounds our CAD table. The paper is Eco Wall Canvas (UFabrik Textile Eco), a material that’s predominantly made from recycled plastic bottles. Sustainability is at the core of what both Imageco and us represent, so this wallpaper was the obvious choice!

Sustainability Peer Network

Throughout the year, the West Yorkshire Combined Authority hosted four Sustainability Peer Network sessions at Greyhound Box. The aim was to unite and inspire local SME leaders on sustainability. And, it was certainly achieved! We were pleased to see new and returning faces attending each session, where experts shared valuable advice on a number of topics. From how to use a carbon footprint calculator to tips of nurturing the next generation of manufacturers, there was plenty of knowledge shared and taken away. Thank you to everyone who attended one or all of these sessions!

Attendees at one of our Sustainability Peer Network sessions

See You in 2025

The time to close our factory shutters for the last time in 2024 nears. Here’s to another year with just as much to celebrate! We look forward to working with our current and new clients, partners, and people in 2025.

Merry Christmas, from all of us at Greyhound Box