How to Reduce the Carbon Footprint of Packaging

When we talk about the carbon footprint of packaging, we’re referring to the total amount of carbon dioxide (CO2) and other greenhouse gases (like methane) produced during the lifecycle of a package. By lifecycle, we mean from the moment materials involved in manufacturing the package are sourced all the way through to the recycling or disposal of the package. Along the way, machines are run, pallets are moved, and packages are transported. These activities all contribute to the carbon footprint of packaging, so you can see how quickly it adds up.

It’s imperative the amount of CO2 packaging contributes to is reduced. Naturally, it’s a core responsibility of packaging manufacturers (like us!), as well as our clients, suppliers, and partners along the supply chain. Read on to learn what we’re doing to reduce the carbon footprint of packaging manufactured at Greyhound Box. And, why you need to make it a priority for the products your business is shipping.

How do We Calculate the Carbon Footprint of Packaging?

For carbon footprint calculations, we use carbon dioxide equivalents (CO2e) to show the amount of CO2 produced. As of 2022, corrugated boards have a CO2e of 491kg per tonne. (That’s a stat from the European Federation of Corrugated Board Manufacturers (FEFCO)). In 2018, this number was 8% higher (531kg of CO2e/tonne), showing a promising improvement in the footprint of an already eco-friendly material.

Why it’s Important to Reduce the Carbon Footprint of Packaging

Greenhouse gas emissions contribute to global warming. Alarmingly, the world is warming faster than at any point in recorded history, causing weather patterns to change and wildlife, animals, and insects to lose habitats crucial to survival. Climate change also adversely affects us, as humans. There’s higher risk of extreme weather events that can have detrimental effects on life and infrastructure.

It’s no secret the global manufacturing industry is one of the bigger contributors to greenhouse gas emissions. Traditionally, we’ve burned fossil fuels to produce the energy needed to power machinery and fuel transport along the supply chain. As a manufacturer, we recognise the challenge of moving away from long-standing processes to those that prioritise sustainability. But at Greyhound Box, we understand how imperative it is that we do so.

Ways to Reduce the Carbon Footprint of Packaging

The environment, namely a more sustainable one, is one of our core values. And so we’ve made it our responsibility to educate our customers and partners alike on how they can implement more sustainable processes to reduce the carbon footprint of packaging for their products.

1. Make sure materials are sourced sustainably

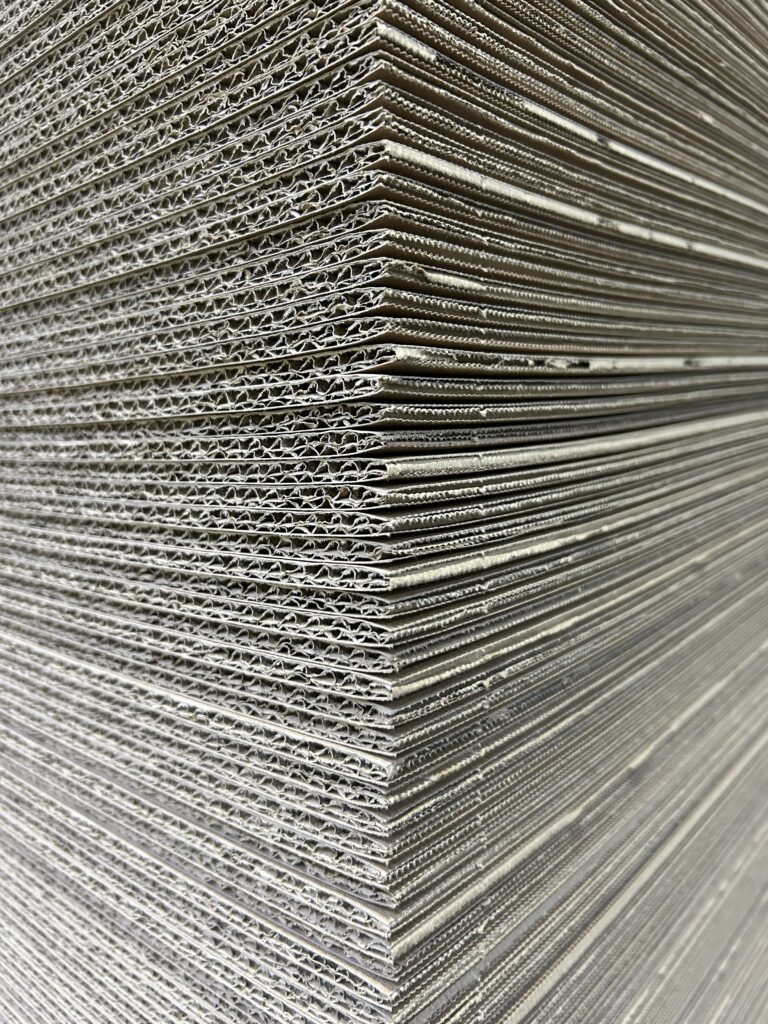

These days, it’s far easier to avoid the use of virgin materials in your product’s packaging. Our corrugated cardboard is certified by the Forest Stewardship Council® (FSC). This means it’s come from a forest that has been managed responsibly, in line with the FSC’s strict requirements.

Our FSC-certified corrugated cardboard

What’s more, corrugated cardboard is one of the easiest materials to recycle. There’s a high chance the board made to package your product has already had one, two, maybe three lives! By opting for recyclable or repurposed materials, you’re lowering the carbon footprint of packaging by reducing the need for the (energy-intensive) mining and production of their virgin counterparts.

2. Prioritise bespoke design

Many customers who use us as their sustainable packaging supplier have one thing in common: packaging they previously used wasn’t optimised to fit and protect their products. When you’ve got a load of unnecessary materials, fillers (like plastic bubblewrap), and seals (always so much tape!), it’s likely the carbon footprint of that package is way higher than it could be.

First up, we carry out a packaging review. This helps us work out what the package needs to have to protect the product and keep it safe along the entire supply chain. By understanding where and how the package is used, we’re better set to develop a bespoke packaging design that aids handling, storage, and transport processes.

Self-sealing sustainable boxes designed and manufactured by Greyhound Box

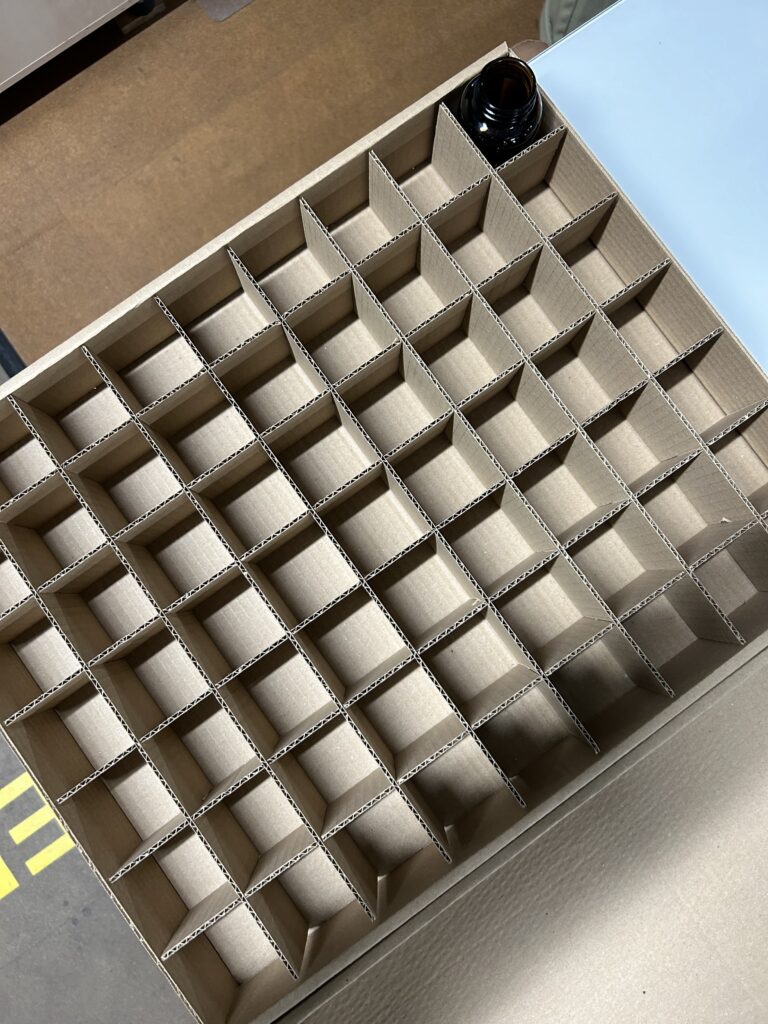

For us, the beauty of bespoke design lies in the ability to think out of the box and be inventive with our sustainable box solutions. For instance, crafting inserts from corrugated cardboard to keep items in place or fillers from recycled papers to protect more fragile goods.

Incorporating sustainable ancillaries (only where they’re essential) means less unnecessary materials that’re likely to go to landfill are within the package. Plus, the package has the required strength to sufficiently protect the goods inside and remain resilient throughout the supply chain. (And usually for reuse after that, too!)

Sustainable packaging inserts manufactured from FSC-certified corrugated cardboard

3. Partner with a sustainable transport and logistics provider

As we said at the top of this blog, the carbon footprint of packaging includes its entire value chain. Choosing a sustainable transport and logistics (T&L) partner is another effective way of bringing that footprint down.

Our transport partner, McDowell’s, is upgrading their fleet of lorries with compressed natural gas-powered tractor units. Over time, this will mean:

- CO2 emissions from the lorries are now reduced by an impressive 80-85%

- The fleet is run by the cleanest burning fuel on the market

- Fewer pollutants are being released into the atmosphere by the T&L of Greyhound Box manufactured boxes

All in all, these units are another piece to the puzzle sorted for reducing the carbon footprint of packaging T&L. We love to see it!

A McDowell’s lorry with compressed natural gas-powered tractor units

Start Reducing the Carbon Footprint of Packaging Today

To reduce the impact of your product’s packaging on the environment, reach out to our team.

Sustainable packaging is our passion, and we’d love to make it yours, too!